Technical Tip for Prosthesis of Antibiotic-Loaded Acrylic Cement (PROSTALAC) Use for Infection after Shoulder Arthroplasty

Robert Spang, MD, Brandon Beamer, MD, Amit Sood, MD, Jon J.P. Warner, MD

Disclosure Information©2015 by The Orthopaedic Journal at Harvard Medical School

BACKGROUND Shoulder arthroplasty procedures have generally excellent clinical outcomes, but infection following shoulder arthroplasty continues to be a difficult problem both diagnostically and therapeutically. Two-stage reimplantation with use of a temporary Prosthesis of Antibiotic-Loaded Acrylic Cement (PROSTALAC) (DePuy, Warsaw, Indiana) is the standard treatment for chronic infection. Optimizing surgical technique regarding cement spacer is a priority, but detailed technical descriptions are sparse.

METHODS The senior author’s original technique for creation of a PROSTALAC implant for shoulder infection following arthroplasty is outlined and illustrated. This includes the use of a custom 44-mm hemispherical mold and a 3.5-mm limited contact dynamic compression plate pre-bent to 125 degrees to mimic the anatomic neck-shaft angle of the humerus. A new technical tip is presented whereby a standard culture tube is injected with antibiotic laden cement followed by plate insertion into the cement-filled tube, thus creating an improved prosthesis with delivery of antibiotics into the humeral canal.

RESULTS A new technical tip is described to improve the creation and insertion of a PROSTALAC implant for patients following infection of shoulder arthroplasty.

CONCLUSION PROSTALAC implants have been successfully used for the treatment of shoulder arthroplasty infections. Implant design and surgical technique can be enhanced to potentially improve outcomes.

Shoulder arthroplasty procedures have increased dramatically over the last several decades with generally excellent clinical outcomes and satisfactory long-term survival rates.1 However, infection following shoulder arthroplasty continues to be a difficult problem presenting challenges both diagnostically and therapeutically. As opposed to prosthetic infections of the hip and knee, treatment algorithms are not well defined and shoulder surgery textbooks contain little information concerning the therapy of infected shoulder replacements.2 The prevalence of infection ranges from approximately 1% to 5%, with a higher rate associated with revision arthroplasty.3-5

Two-stage revision with use of a temporary Prosthesis of Antibiotic-Loaded Acrylic Cement (PROSTALAC) (DePuy, Warsaw, Indiana) is the standard treatment for chronic infection (defined as that persisting for more than four weeks postoperatively) at the site of knee and hip arthroplasty.6 The PROSTALAC implant elutes a high concentration of local antibiotics while maintaining appropriate periarticular soft-tissue tension and preventing capsular and ligament contracture. The quality of apposition between bone-cement interfaces is important in determining the longevity and stability of an antibiotic spacer as well as a cemented prosthesis. Optimizing surgical technique regarding cement spacer creation and implantation is a priority because the prosthesis’ surface properties and shape impact stability.7

Detailed technical descriptions of PROSTALAC use in the shoulder are sparse but potentially useful for the surgeon faced with treating this challenging problem. Here we share a technical tip regarding the creation of a shoulder PROSTALAC implant, illustrating an evolution of the senior author’s preferred technique.

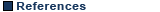

The senior author’s original technique used a 3.5-mm limited contact dynamic compression plate (LC-DCP) pre-bent to approximately 125 degrees to mimic the anatomic neck-shaft angle. The length was made to be similar to a broach trial. The antibiotic cement was mixed in the standard fashion and was placed in a custom 44-mm hemispherical mold (Figure 1). Cement was made with a combination of antibiotic powder (typically 2 g of gentamicin, 3 g of tobramycin, and 1 g of vancomycin per 40-g bag of cement) and Simplex cement (Stryker, Kalamazoo, Michigan) (typically three 40-g bags with four polymethylmethacrylate monomers). The pre-bent plate was then placed and held in the hemispherical mold during cement hardening. This construct was then subsequently inserted with the hemispherical spacer component articulating with the glenoid surface, and the plate inserted directly into the canal. No cement was inserted surrounding the plate within the canal, and no additional fixation of plate to bone was created (Figure 2).

While this technique has been used with success, there is the potential for an improved success rate with the addition of antibiotic cement surrounding the distal portion of the plate to improve plate coverage and possibly improve stability. This new technical tip is described here.

We begin with a similar setup, creating the hemispherical spacer via custom 44-mm mold. While this cement is setting, a standard sterile culture tube is obtained. After curetting and irrigating the humeral canal, the culture tube is inserted into the canal to judge the length of the PROSTALAC stem. The tube is then marked at its top insertion point. This gives the depth of the planned cement plug.

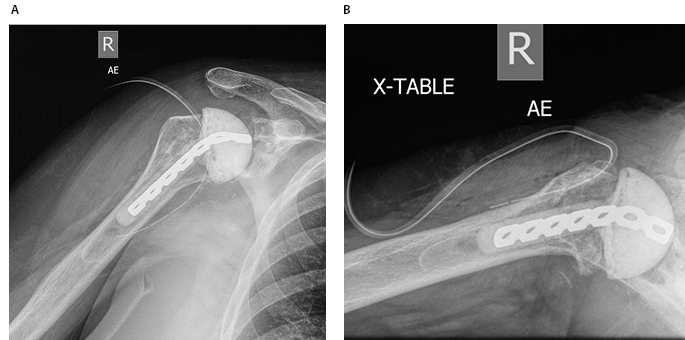

A second batch of cement is mixed. The inside surface of the culture tube is wiped with xeroform to prevent adhesion of cement, and the tube is then cut at the previously marked point. Then, while the cement still has low viscosity, it is placed into a 10-cc syringe and injected into the culture tube. The 3.5-mm plate (with attached hemispherical spacer) is then inserted into the cement-filled tube. The width of the 3.5-mm LC-DCP is the same as the inner diameter of the culture tube, creating a flush fit of the edges of the plate with the tube. Once the cement is doughy, it is then added proximally by hand to cover the entirety of the plate.

Once the cement has hardened, the tube mold is incised with a 10-blade and peeled off the stem.

The final PROSTALAC construct (Figures 3 and 4) is then inserted into the canal using an impactor as needed. No incidences of fracture have been noted with this gentle impaction. If the PROSTALAC implant is too large to fit within the humeral canal, a burr can be used to carefully remove small amounts of bone within the canal to allow the PROSTALAC to be fully seated. Care must be taken to avoid removing excessive bone or perforating the cortex.

Studies investigating outcomes on the treatment of infection following shoulder arthroplasty are limited and do not show the generally favorable outcomes seen with treatment of infections following hip and knee arthroplasty. The use of PROSTALAC for treatment of infection following shoulder arthroplasty has been shown to be beneficial. Early studies of PROSTALAC had shown mixed results,8,9 and some have suggested that outcomes of single-stage reimplantation of reverse total shoulder replacement are equivalent to two-stage reimplantation.9 However, in the largest study on this PROSTALAC use, Jawa and Warner showed that infection was initially eradicated in twenty-three (82%) of twenty-eight patients, more than half had mild or no pain, and 43% of patients declined a second-stage procedure because of acceptable function and pain relief.10 It should be noted that this study employed the first generation technique of having antibiotic laden cement in the joint only, not in the humeral canal. In some cases rotation of the PROSTALAC implant occurred due to lack of intramedullary stability; thus our recent modification seems to give more immediate rotational stability than the prior technique used by the senior author.

Prior studies share limited information of technical details. Jerosch and Schneppenheim state that “a temporary spacer was prepared using antibiotic-loaded cement and additionally stabilized (e.g. by Harrington rods or similar devices)”.11 In the aforementioned study, Jawa and Warner describe and illustrate their prior technique of using PROSTALAC to create an antibiotic cement implant. In that study, three spacers were made without any additional structural support, fourteen were constructed around a one-third tubular plate, and eleven were made around a 3.5-mm limited contact dynamic compression plate. They found that PROSTALAC implants can fracture or dislocate, which was observed in four of their patients (only one of whom needed a revision).10 All three fractures occurred around implants with a one-third tubular plate, prompting a switch to a limited contact-dynamic compression plate scaffold.

Antibiotics are eluted from the surface and pores of cement as well as from the microcracks within it. While elution characteristics vary by brand, the amount of antibiotic delivered also depends on the overall surface area of the implant. As such, a more fully-coated plate would be expected to elute more antibiotic.

One limitation of this technique is that the same culture tube is used regardless of patient humeral canal size, and the canal was not reamed. As such there may be size mismatch between the PROSTALAC and canal. Additional studies will be important to further investigate outcomes of shoulder infections treated with PROSTALAC using this technique.

Use of a PROSTALAC implant for possible two-stage reimplantation is a more conservative approach that has been well-studied and has been found to yield acceptable outcomes with hip and knee arthroplasty in terms of infection eradication and restoration of function. It may also serve as an acceptable permanent treatment. This new technical tip is important in that it achieves complete implant coverage with antibiotic cement, and may improve infection control by addressing bacteria which exist in the canal. In addition, the new construct may be more mechanically stable. This may be significant particularly for those patients for whom the PROSTALAC implant ultimately serves as their final implant.